Mining Waste for Rare Earth Elements

Researchers have devised a easy technique to recuperate treasured scarce earth elements (REEs) from trash. Heating electronic and industrial waste to intensely hot temperatures with flashes of energy can extract extra than 2 times the quantity of REEs from the product than has been achievable with preceding strategies.

REEs, a team of 17 things, are important elements for technologies that make our planet run: smartphones, EV motors, and wind turbines, to title a handful of. But extracting them from the earth is dirty business, producing environmental damage and tons of squander, which includes low-stage radioactive waste.

Then there are global offer-chain challenges. Contrary to their identify, rare earths are basically not that scarce in Earth’s crust. China, on the other hand, has cornered the lion’s share of the market, mining about 70 % of the world’s REEs and processing an even bigger share. To circumvent that stronghold, automakers outside the house China are striving to make electric powered motors that will not use exceptional-earth-containing permanent magnets. Meanwhile, Japan is trying to retrieve the metals from deep-sea mud, and the Metals Co. ideas to mine metallic nodules from the ocean ground.

A extra sustainable resolution for getting scarce earths is to recycle them from old electronics and waste like fly ash, a by-item of burning coal. Salvaging them is difficult, however. REEs really don’t dissolve effortlessly for separation from other components. In fly ash, they are current in the type of phosphates that really don’t commonly split down, and the ash particles are generally encased in a layer of glass that forms in the coal-burning furnace.

REE extraction approaches at the moment in use rely on big quantities of caustic chemical compounds this kind of as acids, and they are inefficient. “You want potent acids to pull them out,” suggests James Tour, a chemist at Rice University. “And powerful acids just cannot even get via glass to get started leeching them out.”

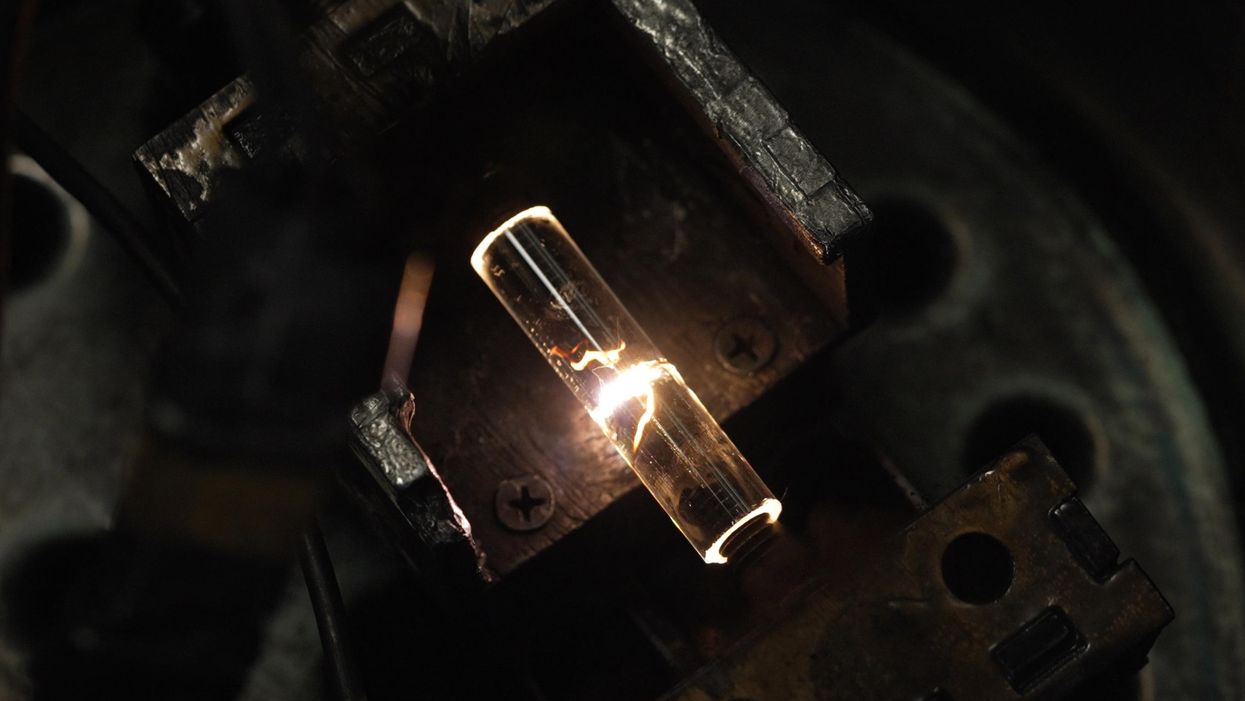

Tour and his colleagues determined to consider utilizing the flash Joule heating procedure they initially formulated in 2020 to make graphene from carbon sources. Previous yr, they claimed employing the strategy to take away precious metals and harmful heavy metals from printed circuit boards. They’ve now determined to switch their interest to REE extraction. “We have the hammer we’re seeking for nails,” Tour claims. “If we could consider trash and get from it these features that we generally strip the earth for, that would be truly excellent.”

In a paper published in Science Advancements, they report working with flash Joule heating on coal fly ash, discarded printed circuit boards, and red mud, the term for the iron-wealthy slurry that is the by-solution of aluminum production. These wastes contain two to 3 moments as considerably of the five most important REEs—yttrium, neodymium, europium, terbium, and dysprosium—as the quantity observed in some of the most concentrated ores in the planet.

Zapping the squander elements with limited, intense bursts of electrical energy rapidly heats them to about 3,000 °C. That is ample to crack the glass layer all over fly ash particles, and to change the REE phosphates located in both of those fly ash and bauxite into oxides that dissolve easily in incredibly delicate acid for subsequent removal. In digital squander, REEs are commonly in the sort of quick-to-dissolve REE metals or oxides, Tour states. But here’s the rub: They are embedded into the matrix supplies in layers, generating them still challenging to take away. Flash Joule heating cracks and separates the matrix layers, making REE separation and removing substantially a lot easier.

As a outcome, the procedure is in a position to extract significantly a lot more rare earths than the conventional process employing sturdy acids. “The concentrated acids that have been the gold common weren’t acquiring all the REEs out of fly ash,” Tour says, “so we’re finding 150 to 200 per cent generate when compared to that earlier common.” What is actually extra, the new method does not use much warmth, and the vitality it uses would value US $12 for every tonne of fly ash when utilized on substantial scale.

Tour claims he and his colleagues’ new approach has caught the focus of persons in the REE industry. And from them he has acquired that this novel method will not be an end-all. “This does not solve everything,” he claims. “You still get mixtures of REEs and there are standard techniques for separating these, but individuals can be main cost details as perfectly. So this gives a new tool to tackle the dilemma, but there are nonetheless other concerns that have to be solved.”

Other scientists are also making an attempt to crack the trouble of extracting REEs from waste. Past week, a staff from Lawrence Livermore Nationwide Laboratory and Pennsylvania State University introduced that they are operating with Western Scarce Earths to acquire a method that makes use of a a short while ago found natural protein to extract unusual earths. And the U.S. Division of Energy announced that it options to establish the 1st substantial-scale facility to extract REEs and other vital metals from mine squander.