Iron Powder Passes First Industrial Test as Renewable, Carbon Dioxide-Free Fuel

Very simple question: What if we could control this total fossil gas-fed climate change nightmare and burn up something else as an electrical power source instead? As a reward, what if that something else is one particular of the most frequent components on Earth?

Very simple remedy: Let us burn up iron.

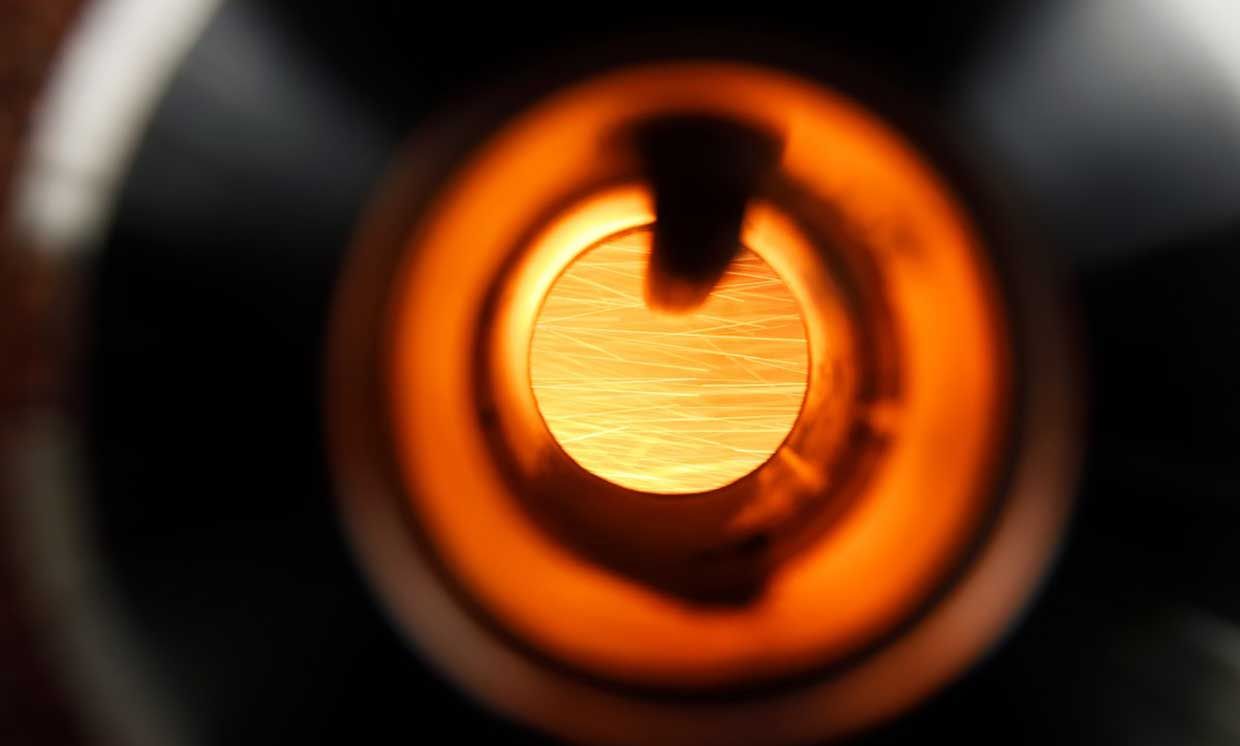

When environment fireplace to an iron ingot is probably much more difficulty than it is worth, fine iron powder blended with air is remarkably flamable. When you burn up this combination, you’re oxidizing the iron. Whereas a carbon gas oxidizes into COtwo, an iron gas oxidizes into FetwoOthree, which is just rust. The great matter about rust is that it is a solid which can be captured submit-combustion. And that is the only byproduct of the overall business—in goes the iron powder, and out comes electrical power in the form of heat and rust powder. Iron has an electrical power density of about eleven.three kWh/L, which is greater than gasoline. Though its precise electrical power is a comparatively bad 1.four kWh/kg, which means that for a supplied total of electrical power, iron powder will take up a minor little bit significantly less space than gasoline but it’ll be almost ten times heavier.

It may not be ideal for powering your car or truck, in other terms. It probably will not heat your household both. But it could be best for industry, which is in which it is getting tested ideal now.

Scientists from TU Eindhoven have been building iron powder as a simple gas for the past a number of a long time, and very last thirty day period they mounted an iron powder heating method at a brewery in the Netherlands, which is turning all that stored up electrical power into beer. Given that electrical energy just can’t proficiently deliver the kind of heat demanded for numerous industrial apps (brewing bundled), iron powder is a practical zero-carbon option, with only rust still left about.

So what takes place to all that rust? This is in which factors get clever, since the iron isn’t just a gas that is consumed— it is electrical power storage that can be recharged. And to recharge it, you take all that FetwoOthree, strip out the oxygen, and switch it again into Fe, prepared to be burned all over again. It’s not effortless to do this, but much of the electrical power and operate that it will take to pry these Os absent from the Fes get returned to you when you burn up the Fe the following time. The thought is that you can use the exact iron about and about all over again, discharging it and recharging it just like you would a battery.

To retain the zero-carbon mother nature of the iron gas, the recharging method has to be zero-carbon as effectively. There are a selection of unique means of working with electrical energy to switch rust again into iron, and a consortium led by TU/e scientists is discovering a few unique systems centered on sizzling hydrogen reduction (which turns iron oxide and hydrogen into iron and h2o), as they explained to us in an e mail:

Mesh Belt Furnace: In the mesh belt furnace the iron oxide is transported by a conveyor belt via a furnace in which hydrogen is additional at 800-1000°C. The iron oxide is minimized to iron, which sticks with each other since of the heat, ensuing in a layer of iron. This can then be ground up to obtain iron powder.

Fluidized Bed Reactor: This is a common reactor sort, but its use in hydrogen reduction of iron oxide is new. In the fluidized mattress reactor the reaction is carried out at decreased temperatures all around 600°C, averting sticking, but having more time.

Entrained Circulation Reactor: The entrained movement reactor is an attempt to put into practice flash ironmaking technology. This strategy performs the reaction at high temperatures, 1100-1400°C, by blowing the iron oxide via a reaction chamber with each other with the hydrogen movement to prevent sticking. This may be a superior answer, but it is a new technology and has nonetheless to be verified.

The two production of the hydrogen and the heat needed to run the furnace or the reactors involve electrical power, of training course, but it is grid electrical power that can arrive from renewable sources.

If renewing the iron gas demands hydrogen, an obvious question is why not just use hydrogen as a zero-carbon gas in the very first position? The challenge with hydrogen is that as an electrical power storage medium, it is tremendous irritating to deal with, given that storing helpful amounts of it generally requires high force and serious chilly. In a localized industrial environment (like you’d have in your rust reduction plant) this isn’t as huge of a deal, but once you start hoping to distribute it, it will become a true headache. Iron powder, on the other hand, is safe and sound to take care of, merchants indefinitely, and can be effortlessly moved with present bulk carriers like rail.

Which is why its potential looks to be in apps in which fat is not a primary concern and selection of the rust is possible. In addition to industrial heat generation (which will sooner or later include things like retrofitting coal-fired power crops to burn up iron powder alternatively), the TU/e scientists are discovering no matter if iron powder could be made use of as gas for significant cargo ships, which are extraordinarily dirty carbon emitters that are also designed to have a whole lot of fat.

Philip de Goey, a professor of combustion technology at TU/e, informed us that he hopes to be able to deploy 10 MW iron powder high-temperature heat methods for industry inside the following 4 a long time, with 10 a long time to the very first coal power plant conversion. There are however difficulties, de Goey tells us: “the technology needs refinement and growth, the marketplace for metallic powders needs to be scaled up, and metallic powders have to be section of the potential electrical power method and regarded as safe and sound and cleanse choice.” De Goey’s see is that iron powder has a significant but effectively-constrained function in electrical power storage, transportation, and production that enhances other zero-carbon sources like hydrogen. For a zero carbon electrical power potential, de Goey claims, “there is no winner or loser— we will need them all.”