Fiber Batteries Power Smart Clothes

We are in a new era of spaceflight: The national area agencies are no lengthier the only video game in city, and area is getting much more obtainable. Rockets designed by business gamers like

Blue Origin are now bringing non-public citizens into orbit. That mentioned, Blue Origin, SpaceX, and Virgin Galactic are all backed by billionaires with massive assets, and they have all expressed intentions to promote flights for hundreds of 1000’s to millions of dollars. Copenhagen Suborbitals has a very unique eyesight. We think that spaceflight really should be available to everyone who’s willing to put in the time and energy.

Copenhagen Suborbitals was launched in 2008 by a self-taught engineer and a area architect who had beforehand labored for NASA. From the beginning, the mission was obvious: crewed spaceflight. Both founders remaining the corporation in 2014, but by then the undertaking had about 50 volunteers and a lot of momentum.

The group took as its founding principle that the issues involved in constructing a crewed spacecraft on the low-cost are all engineering problems that can be solved, one at a time, by a diligent workforce of clever and dedicated men and women. When men and women inquire me why we’re undertaking this, I occasionally solution, “Because we can.”

Volunteers use a tank of argon fuel [remaining] to fill a tube in just which motor things are fused with each other. The workforce lately made a gas tank for the Spica rocket [suitable] in their workshop.

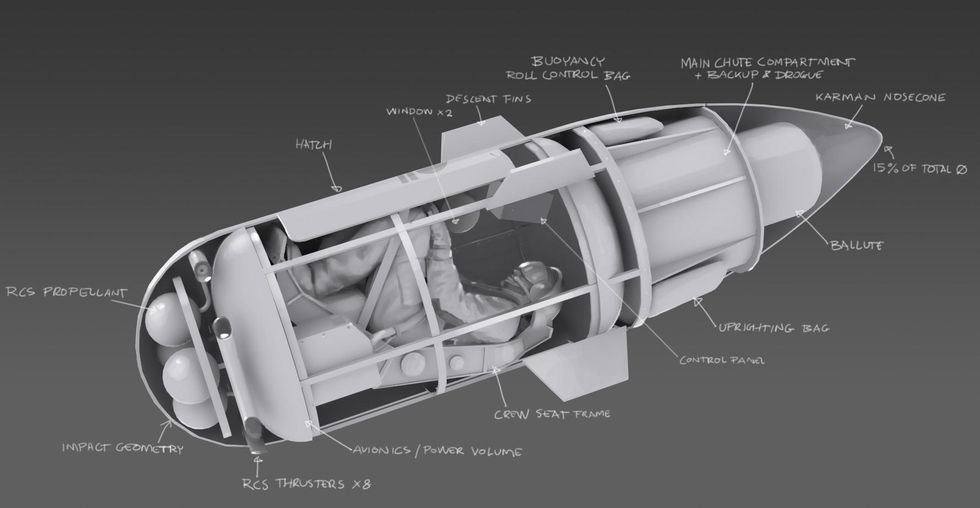

Our target is to get to the Kármán line, which defines the boundary amongst Earth’s ambiance and outer area, a hundred kilometers previously mentioned sea degree. The astronaut who reaches that altitude will have several minutes of silence and weightlessness soon after the engines cut off and will enjoy a breathtaking check out. But it is not going to be an simple ride. Throughout the descent, the capsule will expertise exterior temperatures of four hundred °C and g-forces of 3.five as it hurtles through the air at speeds of up to 3,500 kilometers per hour.

I joined the group in 2011, soon after the corporation had previously moved from a maker area within a decommissioned ferry to a hangar near the Copenhagen waterfront. Earlier that yr, I had watched Copenhagen Suborbital’s to start with start, in which the Warmth-1X rocket took off from a cellular start platform in the Baltic Sea—but regrettably crash-landed in the ocean when most of its parachutes failed to deploy. I brought to the corporation some simple awareness of sports parachutes received during my a long time of skydiving, which I hoped would translate into practical capabilities.

The team’s future milestone came in 2013, when we successfully launched the Sapphire rocket, our to start with rocket to incorporate advice and navigation devices. Its navigation computer utilised a 3-axis accelerometer and a 3-axis gyroscope to keep monitor of its spot, and its thrust-control procedure stored the rocket on the accurate trajectory by transferring four servo-mounted copper jet vanes that were being inserted into the exhaust assembly.

We think that spaceflight really should be available to everyone who’s willing to put in the time and energy.

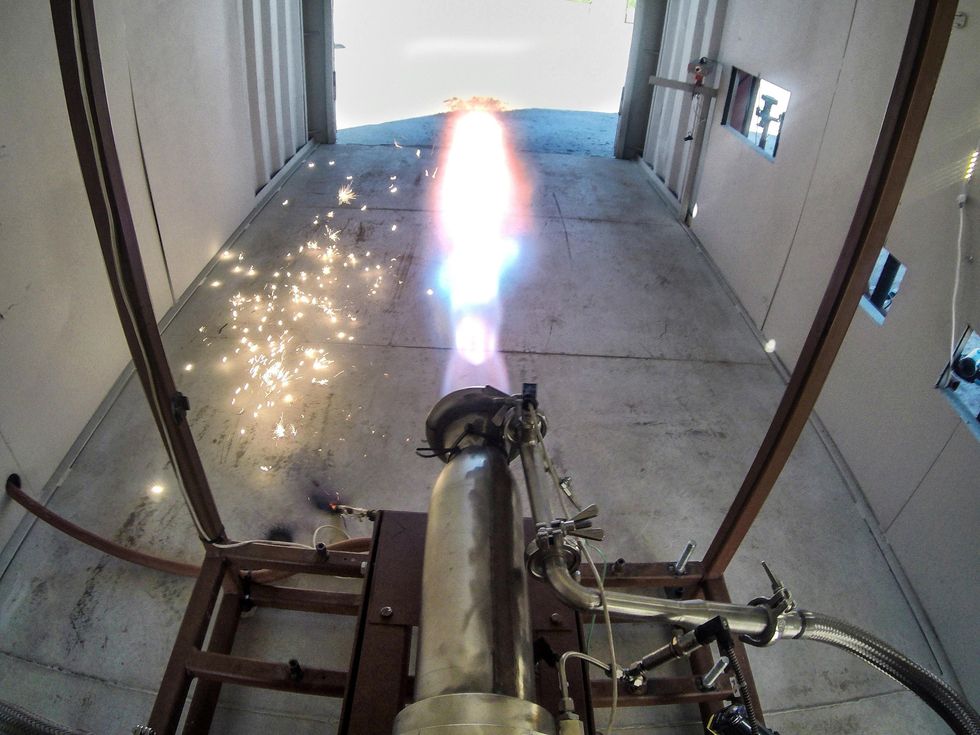

The Warmth-1X and the Sapphire rockets were being fueled with a mix of good polyurethane and liquid oxygen. We were being eager to produce a bipropellant rocket motor that blended liquid ethanol and liquid oxygen, mainly because these kinds of liquid-propellant engines are each effective and strong. The Warmth-2X rocket, scheduled to start in late 2014, was intended to show that engineering. Regretably, its motor went up in flames, pretty much, in a static exam firing some weeks just before the scheduled start. That exam was meant to be a managed ninety-next burn up as a substitute, mainly because of a welding error, a great deal of the ethanol gushed into the combustion chamber in just a handful of seconds, ensuing in a large conflagration. I was standing a handful of hundred meters absent, and even from that distance I felt the warmth on my facial area.

The Warmth-2X rocket’s motor was rendered inoperable, and the mission was canceled. When it was a important disappointment, we discovered some valuable classes. Until finally then, we’d been basing our patterns on our present capabilities—the equipment in our workshop and the men and women on the undertaking. The failure pressured us to just take a stage back and think about what new systems and capabilities we would want to master to get to our conclude target. That rethinking led us to structure the relatively compact Nexø I and Nexø II rockets to show critical systems these kinds of as the parachute procedure, the bipropellant motor, and the pressure regulation assembly for the tanks.

For the Nexø II start in August 2018, our start web site was 30 km east of Bornholm, Denmark’s easternmost island, in a aspect of the Baltic Sea utilised by the Danish navy for military services exercises. We remaining Bornholm’s Nexø harbor at one a.m. to get to the selected patch of ocean in time for a nine a.m. start, the time accredited by Swedish air site visitors control. (When our boats were being in worldwide waters, Sweden has oversight of the airspace previously mentioned that aspect of the Baltic Sea.) Numerous of our crew associates had put in the overall preceding day screening the rocket’s various devices and acquired no snooze just before the start. We were working on espresso.

When the Nexø II blasted off, separating neatly from the start tower, we all cheered. The rocket continued on its trajectory, jettisoning its nose cone when it arrived at its apogee of six,500 meters, and sending telemetry information back to our mission control ship all the although. As it began to descend, it to start with deployed its ballute, a balloon-like parachute utilised to stabilize spacecraft at substantial altitudes, and then deployed its key parachute, which brought it carefully down to the ocean waves.

In 2018, the Nexø II rocket launched successfully [remaining] and returned properly to the Baltic Sea [suitable].

The start brought us one stage nearer to mastering the logistics of launching and landing at sea. For this start, we were being also screening our potential to forecast the rocket’s path. I made a design that believed a splashdown 4.two km east of the start platform it in fact landed 4. km to the east. This managed h2o landing—our to start with underneath a absolutely inflated parachute—was an critical proof of notion for us, because a tender landing is an complete essential for any crewed mission.

This past April, the workforce examined its new gas injectors in a static motor exam. Carsten Olsen

The Nexø II’s motor, which we termed the BPM5, was one of the handful of factors we hadn’t machined totally in our workshop a Danish organization built the most challenging motor parts. But when those parts arrived in our workshop soon just before the start date, we understood that the exhaust nozzle was a minor bit misshapen. We did not have time to get a new aspect, so one of our volunteers, Jacob Larsen, utilised a sledgehammer to pound it into shape. The motor did not appear pretty—we nicknamed it the Franken-Engine—but it labored. Because the Nexø II’s flight, we have exam-fired that motor much more than 30 times, occasionally pushing it over and above its structure limits, but we have not killed it yet.

The Spica astronaut’s fifteen-moment ride to the stars will be the item of much more than two many years of operate.

That mission also demonstrated our new dynamic pressure regulation (DPR) procedure, which helped us control the movement of gas into the combustion chamber. The Nexø I had utilised a simpler procedure termed pressure blowdown, in which the gas tanks were being one-3rd stuffed with pressurized fuel to drive the liquid gas into the chamber. With DPR, the tanks are stuffed to potential with gas and connected by a set of control valves to a different tank of helium fuel underneath substantial pressure. That setup allows us regulate the amount of money of helium fuel flowing into the tanks to push gas into the combustion chamber, enabling us to system in unique amounts of thrust at unique points during the rocket’s flight.

The 2018 Nexø II mission proved that our structure and engineering were being basically sound. It was time to commence doing the job on the human-rated

Spica rocket.

Copenhagen Suborbitals hopes to deliver an astronaut aloft in its Spica rocket in about a ten years. Caspar Stanley

With its crew capsule, the Spica rocket will evaluate 13 meters substantial and will have a gross liftoff weight of 4,000 kilograms, of which two,600 kg will be gas. It will be, by a considerable margin, the most significant rocket ever designed by amateurs.

The Spica rocket will use the BPM100 motor, which the workforce is currently producing. Thomas Pedersen

Its motor, the a hundred-kN

BPM100, works by using systems we mastered for the BPM5, with a handful of advancements. Like the prior structure, it works by using regenerative cooling in which some of the propellant passes through channels close to the combustion chamber to restrict the engine’s temperature. To push gas into the chamber, it works by using a mix of the basic pressure blowdown technique in the to start with period of flight and the DPR procedure, which gives us finer control around the rocket’s thrust. The motor parts will be stainless metal, and we hope to make most of them ourselves out of rolled sheet metallic. The trickiest aspect, the double-curved “throat” segment that connects the combustion chamber to the exhaust nozzle, necessitates computer-managed machining products that we never have. Fortunately, we have excellent sector contacts who can assist out.

Just one important change was the swap from the Nexø II’s showerhead-design gas injector to a coaxial-swirl gas injector. The showerhead injector had about 200 very compact gas channels. It was challenging to manufacture, mainly because if something went erroneous when we were being creating one of those channels—say, the drill acquired stuck—we had to throw the full detail absent. In a coaxial-swirl injector, the liquid fuels appear into the chamber as two rotating liquid sheets, and as the sheets collide, they are atomized to develop a propellant that combusts. Our swirl injector works by using about a hundred and fifty swirler things, which are assembled into one composition. This modular structure really should be less complicated to manufacture and exam for high-quality assurance.

The BPM100 motor will exchange an old showerhead-design gas injector [suitable] with a coaxial-swirl injector [remaining], which will be less complicated to manufacture.Thomas Pedersen

In April of this yr, we ran static tests of several kinds of injectors. We to start with did a trial with a well-recognized showerhead injector to establish a baseline, then examined brass swirl injectors built by classic equipment milling as well as metal swirl injectors built by 3D printing. We were being contented general with the overall performance of each swirl injectors, and we’re however analyzing the information to figure out which functioned superior. Having said that, we did see some

combustion instability—namely, some oscillation in the flames amongst the injector and the engine’s throat, a most likely harmful phenomenon. We have a excellent notion of the lead to of these oscillations, and we’re assured that a handful of structure tweaks can fix the trouble.

Volunteer Jacob Larsen holds a brass gas injector that carried out well in a 2021 motor exam.Carsten Olsen

We are going to before long begin constructing a complete-scale BPM100 motor, which will in the long run integrate a new advice procedure for the rocket. Our prior rockets, in just their engines’ exhaust nozzles, had metallic vanes that we would move to change the angle of thrust. But those vanes generated drag in just the exhaust stream and lowered efficient thrust by about ten p.c. The new structure has

gimbals that swivel the overall motor back and forth to control the thrust vector. As further more assistance for our perception that challenging engineering problems can be solved by clever and dedicated men and women, our gimbal procedure was intended and examined by a 21-yr-old undergraduate scholar from the Netherlands named Jop Nijenhuis, who utilised the gimbal structure as his thesis undertaking (for which he acquired the highest doable quality).

We are making use of the similar advice, navigation, and control (GNC) desktops that we utilised in the Nexø rockets. Just one new obstacle is the crew capsule when the capsule separates from the rocket, we will have to control each individual aspect on its have to provide them each back down to Earth in the sought after orientation. When separation takes place, the GNC desktops for the two factors will want to understand that the parameters for optimum flight have changed. But from a computer software position of check out, which is a slight trouble when compared to those we have solved previously.

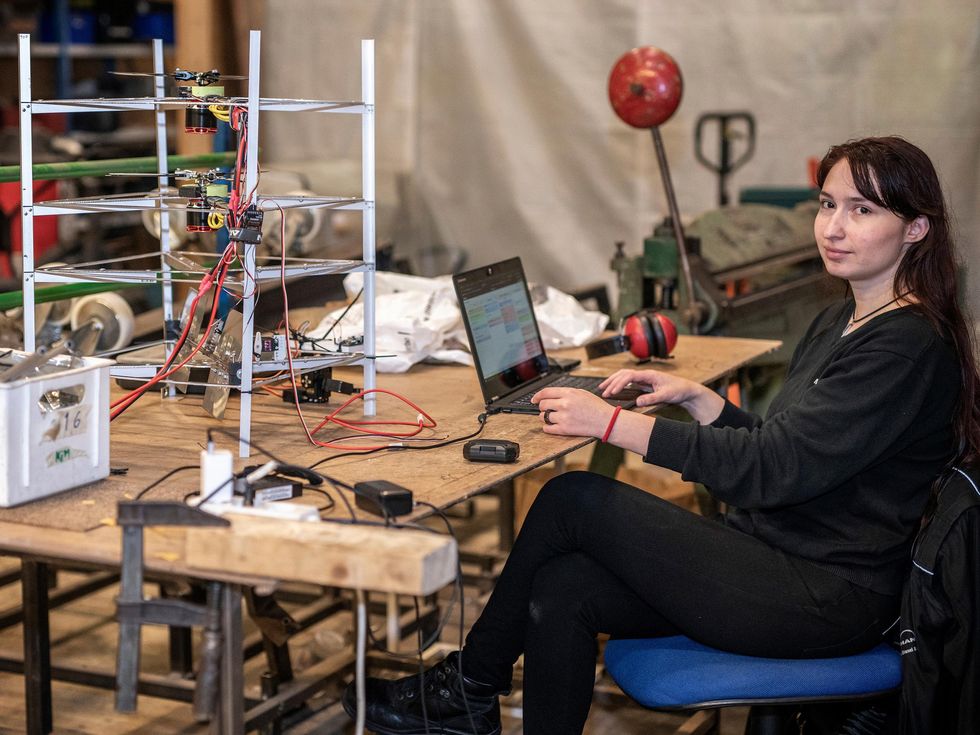

Bianca Diana functions on a drone she’s making use of to exam a new advice procedure for the Spica rocket.Carsten Olsen

My specialty is parachute structure. I have labored on the ballute, which will inflate at an altitude of 70 km to gradual the crewed capsule during its substantial-speed first descent, and the key parachutes, which will inflate when the capsule is 4 km previously mentioned the ocean. We’ve examined each kinds by owning skydivers jump out of planes with the parachutes, most lately in a

2019 exam of the ballute. The pandemic pressured us to pause our parachute screening, but we really should resume before long.

For the parachute that will deploy from the Spica’s booster rocket, the workforce examined a compact prototype of a ribbon parachute.Mads Stenfatt

For the drogue parachute that will deploy from the booster rocket, my to start with prototype was centered on a structure termed Supersonic X, which is a parachute that seems to be somewhat like a flying onion and is very simple to make. Having said that, I reluctantly switched to ribbon parachutes, which have been much more totally examined in substantial-strain situations and uncovered to be much more steady and robust. I say “reluctantly” mainly because I realized how a great deal operate it would be to assemble these kinds of a device. I to start with built a one.24-meter-diameter parachute that had 27 ribbons heading throughout twelve panels, each individual hooked up in 3 places. So on that compact prototype, I had to sew 972 connections. A complete-scale edition will have seven,920 link points. I am making an attempt to keep an open mind about this obstacle, but I also wouldn’t item if further more screening reveals the Supersonic X structure to be adequate for our needs.

We’ve examined two crew capsules in past missions: the Tycho Brahe in 2011 and the Tycho Deep House in 2012. The future-era Spica crew capsule is not going to be spacious, but it will be big sufficient to hold a solitary astronaut, who will continue being seated for the fifteen moments of flight (and for two several hours of preflight checks). The to start with spacecraft we’re constructing is a hefty metal “boilerplate” capsule, a simple prototype that we’re making use of to arrive at a realistic structure and structure. We are going to also use this design to exam hatch structure, general resistance to pressure and vacuum, and the aerodynamics and hydrodynamics of the shape, as we want the capsule to splash down into the sea with small shock to the astronaut within. When we’re content with the boilerplate structure, we will make the lightweight flight edition.

Copenhagen Suborbitals currently has 3 astronaut candidates for its to start with flight: from remaining, Mads Stenfatt, Anna Olsen, and Carsten Olsen. Mads Stenfatt

3 associates of the Copenhagen Suborbitals workforce are currently candidates to be the astronaut in our to start with crewed mission—me, Carsten Olsen, and his daughter, Anna Olsen. We all understand and acknowledge the dangers involved in flying into area on a handmade rocket. In our day-to-day operations, we astronaut candidates never acquire any particular therapy or teaching. Our one extra duty thus significantly has been sitting in the crew capsule’s seat to examine its dimensions. Because our to start with crewed flight is however a ten years absent, the applicant record may well change. As for me, I imagine there is certainly appreciable glory in just currently being aspect of the mission and assisting to build the rocket that will provide the to start with beginner astronaut into area. Whether or not I conclude up currently being that astronaut, I am going to permanently be proud of our achievements.

The astronaut will go to area within a compact crew capsule on the Spica rocket. The astronaut will continue being seated for the fifteen-moment flight (and for the two-hour flight examine just before). Carsten Brandt

Individuals may marvel how we get by on a shoestring finances of about $a hundred,000 a year—particularly when they find out that fifty percent of our profits goes to having to pay hire on our workshop. We keep costs down by getting standard off-the-shelf parts as a great deal as doable, and when we want custom patterns, we’re lucky to operate with providers that give us generous bargains to assistance our undertaking. We start from worldwide waters, so we never have to pay out a start facility. When we travel to Bornholm for our launches, each individual volunteer pays his or her have way, and we continue to be in a sports club near the harbor, sleeping on mats on the floor and showering in the shifting rooms. I occasionally joke that our finances is about one-tenth what NASA spends on espresso. Yet it may well be sufficient to do the work.

We had intended to start Spica for the to start with time in the summer season of 2021, but our program was delayed by the COVID-19 pandemic, which shut our workshop for quite a few months. Now we’re hoping for a exam start in the summer season of 2022, when conditions on the Baltic Sea will be relatively tame. For this preliminary exam of Spica, we will fill the gas tanks only partway and will intention to deliver the rocket to a peak of close to 30 to 50 km.

If that flight is a good results, in the future exam, Spica will have much more gas and soar bigger. If the 2022 flight fails, we will figure out what went erroneous, deal with the problems, and test once again. It’s remarkable to imagine that the Spica astronaut’s eventual fifteen-moment ride to the stars will be the item of much more than two many years of operate. But we know our

supporters are counting down until finally the historic day when an beginner astronaut will climb aboard a handmade rocket and wave goodbye to Earth, ready to just take a big leap for Diy-form.

This write-up appears in the December 2021 print issue as “The Initial Crowdfunded Astronaut.”

A Skydiver Who Sews

HENRIK JORDAHN

Mads Stenfatt to start with contacted Copenhagen Suborbitals with some constructive criticism. In 2011, although on the lookout at photographs of the Diy rocketeers’ newest rocket start, he had found a camera mounted close to the parachute equipment. Stenfatt sent an electronic mail detailing his concern—namely, that a parachute’s lines could conveniently get tangled close to the camera. “The solution I acquired was basically, ‘If you can do superior, appear be part of us and do it yourself,’ ” he remembers. That’s how he grew to become a volunteer with the world’s only crowdfunded crewed spaceflight system.

As an beginner skydiver, Stenfatt realized the simple mechanics of parachute packing and deployment. He started off assisting Copenhagen Suborbitals structure and pack parachutes, and a handful of a long time later on he took around the work of sewing the chutes as well. He had never utilised a sewing equipment just before, but he discovered speedily around evenings and weekends at his eating area desk.

Just one of his favorite jobs was the structure of a substantial-altitude parachute for the Nexø II rocket, launched in 2018. When doing the job on a prototype and puzzling around the structure of the air intakes, he uncovered himself on a Danish sewing web site on the lookout at brassiere factors. He made the decision to use bra underwires to stiffen the air intakes and keep them open, which labored rather well. While he ultimately went in a unique structure course, the episode is a classic illustration of the Copenhagen Suborbitals ethos: Acquire inspiration and assets from where ever you discover them to get the work completed.

Nowadays, Stenfatt serves as direct parachute designer, recurrent spokesperson, and astronaut applicant. He also proceeds to skydive in his spare time, with hundreds of jumps to his title. Acquiring sufficient expertise zooming down through the sky, he’s intently curious about what it would sense like to go the other course.

From Your Web-site Articles

Relevant Articles All over the Net