Enevate’s Silicon Anodes Could Yield EV Batteries That Run 400 km on a 5-Minute Charge

Battery makers have for years been seeking to switch the graphite anode in lithium-ion batteries with a variation created of silicon, which would give electric automobiles a a lot for a longer period variety. Some batteries with silicon anodes are getting near to market place for wearables and electronics. The recipes for these silicon-prosperous anodes that a handful of businesses are creating commonly use silicon oxide or a combine of silicon and carbon.

But Irvine, CA-centered Enevate is working with an engineered porous film created generally of pure silicon. In addition to being reasonably priced, the new anode substance, which founder and main technological know-how officer Benjamin Park has expended extra than 10 years creating, will direct to an electric auto (EV) that has thirty percent extra variety on a solitary charge than today’s EVs. What is extra, the battery Enevate envisions could be charged up enough in 5 minutes to produce four hundred km of driving variety.

Large names in the battery and automotive business are listening. Carmakers Renault, Nissan, and Mitsubishi, as perfectly as battery-makers LG Chem and Samsung, are traders. And lithium battery pioneer and 2019 Chemistry Nobel Prize winner John Goodenough is on the company’s Advisory Board.

When lithium-ion batteries are charged, lithium ions transfer from the cathode to the anode. The extra ions the anode can hold, the better its electricity capability, and the for a longer period the battery can operate. Silicon can in idea hold 10 situations the electricity of graphite. But it also expands and contracts considerably, falling apart following a handful of charge cycles.

To get around that, battery makers these types of as Tesla nowadays insert just a small bit of silicon to graphite powder. The powder is combined with a glue-like plastic known as a binder and is coated on a skinny copper foil to make the anode. But, states Park, lithium ions respond with silicon initially, ahead of graphite. “The silicon nonetheless expands fairly a bit, and that plastic binder is weak,” he states, conveying that the full electrode is extra likely to degrade as the sum of silicon is ramped up.

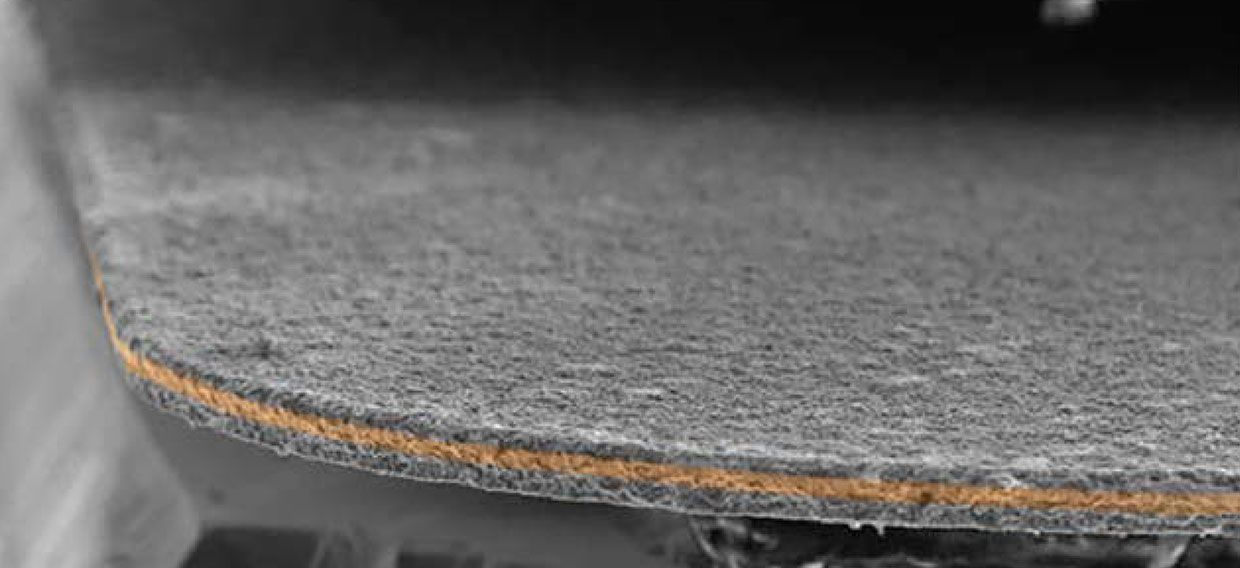

Enevate does not use plastic binders. In its place, its patented procedure makes the porous 10- to sixty-µm-thick silicon film directly on a copper foil. The cherry on leading is a nanometers-thick protective coating, which, states Park, “prevents the silicon from reacting with the electrolyte.” That type of reaction can also harm a battery.

The procedure does not require significant-excellent silicon, so anodes of this type cost less than their graphite counterparts of the identical capability. And mainly because the substance is largely silicon, lithium ions can slip in and out quite quickly, charging the battery to seventy five percent of its capability in 5 minutes, devoid of producing a lot growth. Park likens it to a significant-capability motion picture theater. “If you have a complete motion picture theater it requires a extensive time to find the one particular vacant seat. We have a theater with 10 situations extra capability. Even if we fill that theater halfway, [it nonetheless does not get extensive] to find vacant seats.”

The company’s roll-to-roll processing methods can make silicon anodes quickly ample for significant-quantity producing, states Park. By coupling the silicon anode with traditional cathode products these types of as nickel-manganese-cobalt, they have created battery cells with electricity densities as significant as 350 watt-several hours for every kilogram, which is about thirty percent extra than the precise electricity of today’s lithium-ion batteries. Enevate states it is now working with numerous significant automotive businesses to create typical-measurement battery cells for 2024-25 product 12 months EVs.