A Battery That's Tough Enough To Take Structural Loads

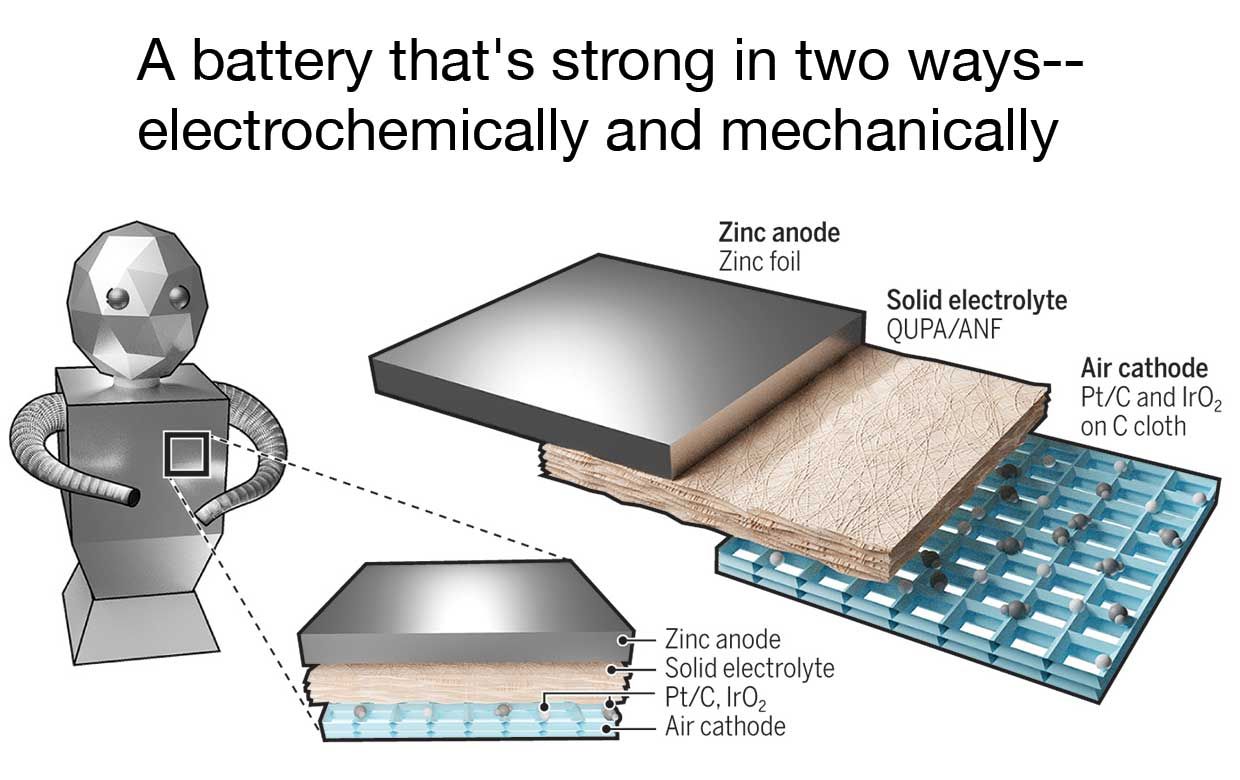

Batteries can incorporate considerable mass to any style, and they have to be supported applying a sufficiently powerful construction, which can incorporate substantial mass of its own. Now scientists at the College of Michigan have developed a structural zinc-air battery, just one that integrates right into the device that it powers and serves as a load-bearing element.

That characteristic saves bodyweight and therefore increases effective storage potential, adding to the currently significant energy density of the zinc-air chemistry. And the pretty factors that make the battery bodily powerful help consist of the chemistry’s longstanding tendency to degrade in excess of several hundreds of charge-discharge cycles.

The investigation is remaining printed today in Science Robotics.

Nicholas Kotov, a professor of chemical engineer, is the leader of the task. He would not say how several watt-hours his prototype shops per gram, but he did note that zinc air—because it draw on ambient air for its energy-producing reactions—is inherently about three periods as energy-dense as lithium-ion cells. And, due to the fact applying the battery as a structural part means dispensing with an inside battery pack, you could cost-free up probably twenty per cent of a machine’s inside. Along with other components the new battery could in basic principle provide as considerably as 72 periods the energy per device of quantity (not of mass) as today’s lithium-ion workhorses.

“It’s not as if we invented something that was there in advance of us,” Kotov states. ”I glance in the mirror and I see my layer of fat—that’s for the storage of energy, but it also serves other purposes,” like retaining you warm in the wintertime. (A comparable advance occurred in rocketry when designers realized how to make some liquid propellant tanks load bearing, removing the mass penalty of acquiring independent external hull and interior tank partitions.)

Other people have spoken of placing batteries, together with the lithium-ion sort, into load-bearing sections in motor vehicles. Ford, BMW, and Airbus, for instance, have expressed interest in the strategy. The most important trouble to get over is the tradeoff in load-bearing batteries between electrochemical overall performance and mechanical strength.

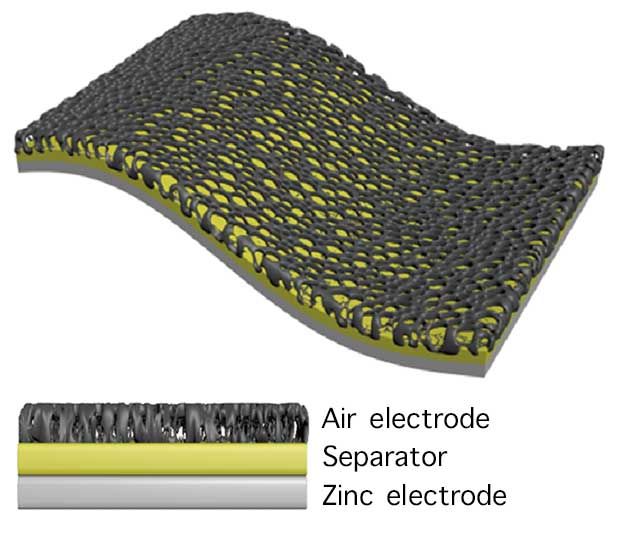

The Michigan group get both traits by using a solid electrolyte (which can not leak beneath worry) and by masking the electrodes with a membrane whose nanostructure of fibers is derived from Kevlar. That would make the membrane tricky adequate to suppress the growth of dendrites—branching fibers of metal that tend to form on an electrode with every charge-discharge cycle and which degrade the battery.

The Kevlar need not be procured new but can be salvaged from discarded entire body armor. Other producing steps really should be quick, also, Kotov states. He has only just begun to converse to prospective business partners, but he states there is no cause why his battery could not strike the sector in the up coming three or 4 decades.

Drones and other autonomous robots may well be the most sensible 1st application due to the fact their variety is so severely chained to their battery potential. Also, due to the fact these robots never carry individuals about, they deal with less of a hurdle from basic safety regulators leery of a basically new battery kind.

“And it’s not just about the major Amazon robots but also pretty little types,” Kotov states. “Energy storage is a pretty substantial challenge for little and adaptable gentle robots.”

Here’s a movie displaying how Kotov’s lab has applied batteries to form the “exoskeleton” of robots that scuttle like worms or scorpions.