Graphene Solar Thermal Film Could Be a New Way to Harvest Renewable Energy

Suppressing thermal emission loss—also identified as blackbody radiation—while simultaneously absorbing solar mild is vital for an effective solar thermal absorber but is extremely difficult to accomplish, claims Baohua Jia, founding director of CTAM. “That’s for the reason that, dependent on the absorbed heat and homes of the absorber, the emission temperature differs, which prospects to considerable distinctions in its wavelength,” she explains. “But we have designed a three-dimensional structured graphene metamaterial (SGM) that is remarkably absorbent and selectively filters out blackbody radiation.”

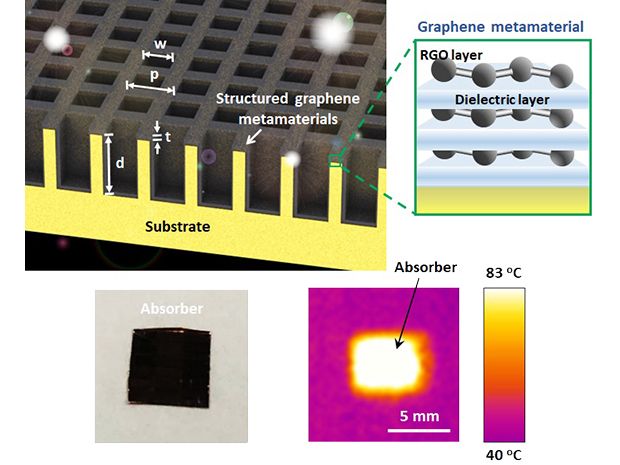

The 3D SGM is composed of a thirty-nanometer-thick film of alternating graphene and dielectric layers deposited on a trench-like nanostructure that does double responsibility as a copper substrate to improve absorption. A lot more importantly, the substrate is patterned in a matrix arrangement to enable versatile tunability of wavelength-selective absorption.

The graphene film is designed to absorb mild among .28- to 2.5-micrometer wavelengths. And the copper substrate is structured so that it can act as a selective bandpass filter that suppresses the usual emission of internally produced blackbody energy. This retained heat then serves to even further elevate the metamaterial’s temperature. As a result, the SGM can quickly heat up to eighty three degrees C. Need to a distinct temperature be essential for a distinct application, a new trench nanostructure can be fabricated and tuned to match that specific blackbody wavelength.

“In our prior perform, we shown a 90 nm graphene heat-absorbing product,” claims Baohua. While it could heat up to 160 degrees C, “the structure was a lot more intricate, [comprising] four layers: a substrate, a silver layer, a layer of silicon oxide, and a graphene layer. Our new two-layer structure is easier and does not need vacuum deposition. And the system of fabrication is scalable and lower cost.”

The new product also uses less graphene by drastically minimizing the film thickness to one particular 3rd, and its thinness aids in transferring the absorbed heat a lot more successfully to other media such as h2o. Additionally, the film is hydrophobic, which fosters self-cleansing, though the graphene layer properly safeguards the copper layer from corrosion, assisting to increase the metamaterial’s lifetime.

“Because the metallic substrate’s structural parameters are the major variables governing overall absorption effectiveness of the SGM, fairly than its intrinsic characteristics, distinct metals can be applied according to application requires or cost,” claims Keng-Te Lin, guide writer of a paper on the metamaterial not too long ago printed in Mother nature Communications, and who is also a investigate fellow at Swinburne University. Aluminum foil can also be applied to change copper without the need of compromising the effectiveness, he notes.

To exam the metamaterial’s design and security, the scientists fabricated a prototype making use of standard laser nanofabrication, self-assembly graphene oxide coating, and image-induced reduction.

“We applied the prototype film to produce cleanse h2o and accomplished an remarkable solar-to-vapor performance of 96.2 p.c,” claims Keng-Te. “This is quite aggressive for cleanse h2o era making use of a renewable energy supply.”

He provides that the metamaterial can also be applied for energy harvesting and conversion apps, steam era, wastewater cleansing, seawater desalination, and thermoelectricity era.

A single challenge still remaining is finding a manufacturing system for producing the substrate scalable.

“We are functioning with a personal business, Innofocus Photonics Technology, that has commercialized a coating device to lay down the graphene and dielectric layers,” claims Baohua. “And we are content with that. What we are now wanting for is a acceptable system for significant scale creation of the copper substrate.” A single risk, she provides, is making use of a roll-to-roll course of action.

Meanwhile, the scientists are continuing to great-tune the nanostructure design and increase the SGM’s security and absorption performance. “As for commercialization,” claims Baohua, “we feel that will be possible in one particular to two several years.”