Redox-Flow Cell Stores Renewable Energy as Hydrogen

“Hydrogen is a extremely very good carrier for this style of perform,” claims Wei Wang, who is the main scientist for stationary power storage study at the Pacific Northwest National Laboratory in Washington. It is an effective power carrier, and can be quickly saved in pressurized tanks. When essential, the gasoline can then be converted back into electrical power by using a fuel mobile and fed into the grid.

But drinking water electrolyzers are highly-priced. They perform below acidic conditions which need corrosion-resistant metallic plates and catalysts created from valuable metals this sort of as titanium, platinum, and iridium. “Also, the oxygen electrode is not extremely effective,” claims Kathy Ayers, vice-president of R&D at Nel Hydrogen, an Oslo-based corporation that specializes in hydrogen production and storage. “You eliminate about .three volts just from the simple fact that you’re trying to convert drinking water to oxygen or vice versa,” she claims. Splitting a drinking water molecule necessitates an used voltage of one.23 V.

In a bid to get over this dilemma, Nel Hydrogen and Wang’s crew at Pacific Northwest joined forces in 2016, immediately after obtaining funding from the U.S. Division of Energy’s Superior Investigate Assignments Company-Electricity. The alternative they’ve arrive up with is a fuel mobile that functions as both a battery and hydrogen generator.

“We phone it a redox-circulation mobile since it’s a hybrid involving a redox-circulation battery and a drinking water electrolyzer,” points out Wang.

A redox-circulation battery, in essence a reversible fuel mobile, is ordinarily created up of a positive and unfavorable electrolyte saved in two separate tanks. When the liquids are pumped into the battery mobile stack situated involving the tanks, a redox response occurs, and generates electrical power at the battery’s electrodes.

By comparison, the new invention has only one electrolyte, comprised of an iron salt (relatively than the a lot more typically made use of vanadium) dissolved in acid. When hydrogen ions respond with the iron salt (Fetwo+), hydrogen gasoline is created at the platinum-coated carbon cathode in the battery stack.

“We introduce iron as a intermediary, so we can separate electrolysis into two reactions,” claims Wang. Doing so makes it possible for one to control the place and when to reverse the response to make electrical power to offer to the grid. “The process presents you adaptability… you could do the regeneration for the duration of evening time when electrical power selling prices are at a peak,” he claims.

Regenerating Fetwo+ in the reverse response also makes it possible for for the steady production of hydrogen gasoline, he claims. “And since the hydrogen-iron mobile uses about 50 % the voltage of a regular electrolyzer, you can deliver hydrogen at a a great deal much less expensive value if you do all the things proper.”

It also can help that iron is a great deal much less expensive and a lot more abundant as opposed with vanadium.

Qing Wang, a elements scientist at the National University of Singapore, sees a different profit. “If you care a lot more about purity and want to have ultra-pure hydrogen, then possibly it’s a very good alternative,” he claims. Cross-contamination can occasionally take place for the duration of electrolysis since the hydrogen and oxygen gases created are so compact that they are equipped to traverse the membrane separator.

The new redox-circulation mobile performed perfectly in lab tests, exhibiting a cost capability of up to one ampere for each square centimeter, a ten-fold improve more than usual circulation batteries. It was also equipped to face up to “several hundred cycles” of charging, which has never been demonstrated before in hydrogen ion circulation batteries, claims Wang, who has a range of patents for the invention, with a few a lot more pending.

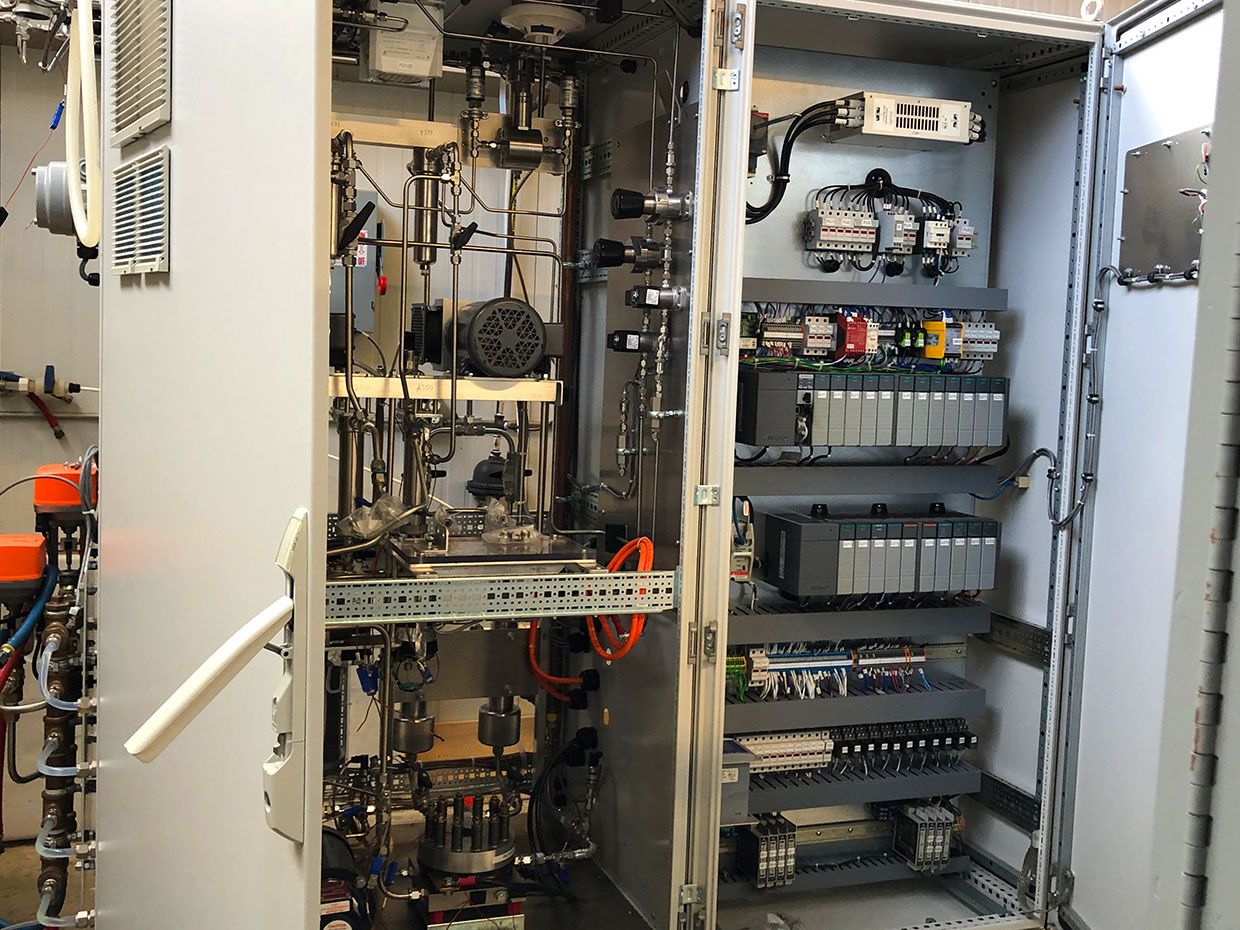

While the PNNL crew experimented on a solitary mobile measuring ten square centimeters, Ayers and her colleagues at Nel Hydrogen proved that the engineering could perform even when scaled up to a 5-mobile stack measuring a hundred square centimeters. They system to devote the upcoming few months fine-tuning the process and reducing kinks, this sort of as how to decrease harm to the pumps prompted by the acidic electrolyte, before commercializing it.

This article was current on 20 April 2020.